BOMB DISPOSAL TOOLS

Lock ring spanner.

Bomb Disposal engineers were faced with two immediate challenges making a bomb safe in 1939, firstly how to remove the locking ring that held the fuze in place and secondly removing the fuze from the bomb safely.

The first two pieces of kit developed for this were the "Lock ring spanner" and the "Crabtree Discharger".

Bomb Disposal engineers were faced with two immediate challenges making a bomb safe in 1939, firstly how to remove the locking ring that held the fuze in place and secondly removing the fuze from the bomb safely.

The first two pieces of kit developed for this were the "Lock ring spanner" and the "Crabtree Discharger".

|

To tackle the fuzes locking ring, two types of lock ring spanner were developed. both did the same job, but both had their limitations when the lock ring was seized in place. Thus requiring the bomb disposal engineer to resort to the original method of gently tapping the ring round with a chisel and hammer.

|

|

Crabtree Discharger.

The first thing to do even before removing the lock ring was to discharge the electric charge in the bomb fuze capacitor, in order for the fuze to be removed safely. This was achieved by placing the Crabtree discharger over the two pins of the Fuze and clamping the discharger to the Fuze with the thumb screw. At this point you had to wait to let the Fuze capacitor to discharge, after which you could gently remove the locking ring, tie a length of string to the discharger and gently pull the fuze out as far away from the bomb as possible. |

|

However, the Germans soon learnt about the development of the tool being used on the type 15 Fuze. Very quickly the now obsolete Type 15 Fuze was replaced with the similar looking Type 25 Fuze which had the electrical circuit changed so if the terminals were shorted the bomb would go off if a Crabtree Discharger was used.

The Crabtree discharger evolved, with the prongs of the discharger being removed allowing it to be used just as a Fuze removal tool. |

With the Crabtree discharger only able to be used as removal tool, another method of making the bomb safe was needed

as well as a more effective lock ring removal tool.

as well as a more effective lock ring removal tool.

|

Quilter Fuze Key

Quite frequently the locking ring holding the Fuze in the bombs pocket would be too much for the lock ring spanners, in the early days the BD engineer would revert to using a hammer and chisel to tap the ring round. The quilter Fuze key was developed to make the removal of a seized Fuze, quicker and a lot safer than using the hammer and chisel. It worked like a modern oversize socket wrench, that clamped onto the locking ring. |

|

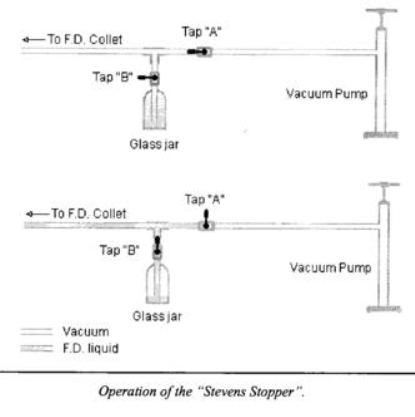

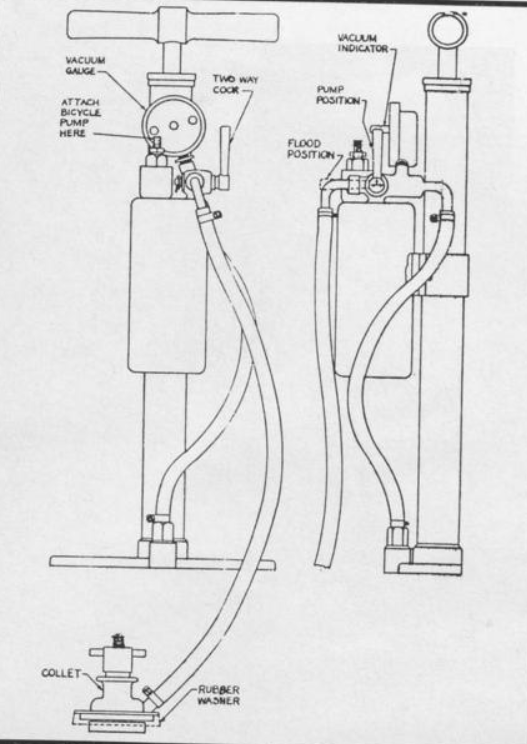

Liquid fuze discharger.

The liquid fuze discharger was developed kill the electrical circuit of the fuze, to achieve this BD fluid was forced into the fuze after drilling a small hole thus destroying the electrical circuitry. The liquid Fuze discharger was effectively just a bicycle pump pressurising the BD fluid bottle, allowing the liquid to squirt in under pressure into the Fuze. The BD Fluid used was made up of a caustic mix of Benzol, methylated spirit, salt and food colouring |

|

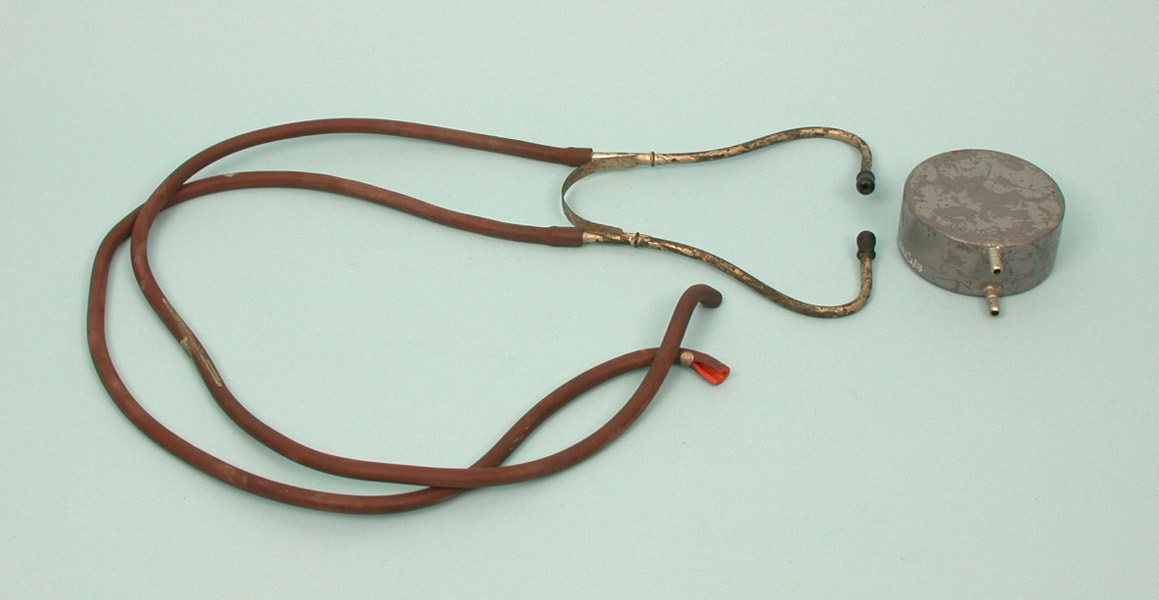

Acoustic stethoscope.

The acoustic stethoscope speaks for itself really. Bomb disposal engineers realised that with the type 17-time delay Fuzes they could use a standard doctor's stethoscope to listen for the ticking. This was a useful tool, in conjunction with the stopper tools, to verify the stopper tools were actually working. Towards the later part of the war, an electronic stethoscope had been developed. |

|

|

Magnetic Clock Stopper.

The type 17 delayed-action fuse located at the nose end of a two Fuze bomb, was governed by a clockwork mechanism set to ignite at a pre-determined moment within a period of 72 hours. Up to the development of the magnetic clock stopper there was no safe way of removing the time delay Fuze. The magnetic clock-stopper was a large coil of wire about the size of a car wheel, which when powered up became a massive electromagnet. when this was sat around the type 17 clockwork fuze the powerful magnetic field was enough to stop the Fuzes mechanism and therefore stop the bomb exploding. The use of the Stethoscope was the method to confirm the clock was not ticking. |

Clock-stopper” or Q-coil was about the size of a horse collar and weighed 90kg and was powered from a 140VDC source and came with an electronic stethoscope to check that the ticking had stopped. Once the clock-stopper was applied, the bomb could be moved to a safe location for further work.

Later deployed in improved form, the K.I.M. could injected urea formaldehyde resin into the fuse which Solidified and jammed the mechanism

Later deployed in improved form, the K.I.M. could injected urea formaldehyde resin into the fuse which Solidified and jammed the mechanism

|

steam steriliser.

The steam steriliser was designed to be clamped around the bomb, allowing it to cut a hole in the top of the bomb casing and emulsify the explosive before forcing it out under pressure. The first stage was to drill a hole in the casing of the bomb using the trepanning head, this was done by using the steam generated to turn a motor with a large drill bit fitted. Once there was a hole in the bomb, the steam used to power the drill was routed into the bomb. |

|

Firing Circuit Detector.

This instument is a galvanometer, known as a ‘Q and I detector’. and was used as the basic diagnostic tool by BD Officers. A horizontal axle carries an indicator in front of the dial and a magnetised needle inside, located between two coils. Two inclined bar magnets helped maintain the magnetisation of the needle. The higher resistance coil was connected to indicate voltage (‘Intensity’)and the lower resistance coil was used to indicate current (‘Quantity’). Its main use was for testing electrical firing circuits. |